Grain Bin Moisture Monitoring: Ensuring Quality Harvests and Maximizing Profitability

In the ever-evolving agricultural landscape, maintaining the quality of harvested crops is paramount. Grain bin moisture monitoring has emerged as an essential practice for farmers who wish to safeguard their grain storage, ensuring optimal moisture levels and preventing spoilage. This article delves into the significance of moisture monitoring and offers insights into best practices, technological advancements, and how this process can ultimately increase profitability for farmers.

Understanding Grain Bin Moisture Monitoring

### What is Grain Bin Moisture Monitoring?

At its core, grain bin moisture monitoring is the process of managing and measuring moisture content within grain storage facilities. Successfully managing this aspect of grain storage is crucial because it directly influences the shelf life of grains, their quality, and their market value.

Why is Moisture Monitoring Important?

Moisture levels that are too high can lead to a host of problems, including:

- Mold growth: Excess moisture fosters molds that can spoil grain and make it unsafe for consumption.

- Insect infestations: Insects are attracted to moist environments and can ruin stored grains.

- Reduced marketability: Grain with high moisture content typically fetches lower prices on the market.

Benefits of Grain Bin Moisture Monitoring

1. Enhanced Quality Control

Monitoring moisture levels allows farmers to maintain the quality of their grains through optimal storage conditions. Keeping moisture levels within recommended ranges helps to preserve grain nutrients and prevents deterioration.

2. Prevention of Spoilage

By constantly monitoring moisture content, farmers can take preventive actions before spoilage occurs. This proactive approach protects the financial investment made in crops and contributes to higher yields at the point of sale.

3. Increased Profitability

Farms that effectively utilize grain bin moisture monitoring see a direct correlation between well-maintained storage conditions and profit margins. By ensuring that crops meet the quality standards set by the market, farmers can negotiate better prices for their produce.

Technologies in Grain Bin Moisture Monitoring

The integration of technology in grain bin moisture monitoring has revolutionized the agricultural sector. Some of the key advancements include:

1. Digital Moisture Meters

Modern moisture meters provide instant moisture readings, allowing farmers to react swiftly to any changes. These devices can be integrated with mobile apps, providing real-time data no matter where the farmer is located.

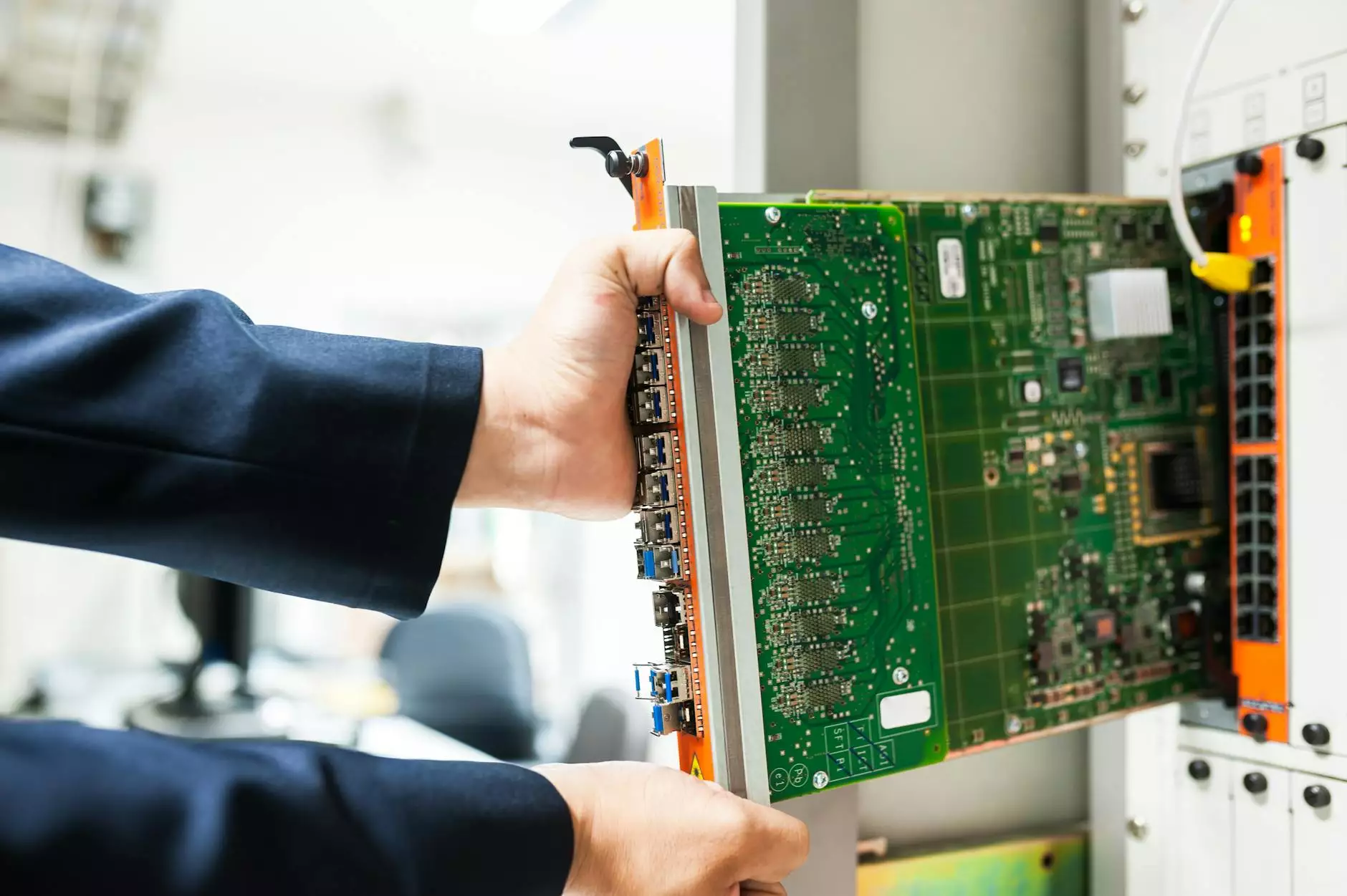

2. Automated Monitoring Systems

Advanced automated systems can continuously monitor moisture levels, send alerts when levels fluctuate, and even control ventilation systems within bins to maintain optimal conditions.

3. Internet of Things (IoT) Solutions

The IoT has made it possible to collect and analyze moisture data from multiple bins in real-time, offering valuable insights that can drive better decision-making regarding storage and marketing strategies.

Best Practices for Grain Bin Moisture Monitoring

To maximize the benefits of grain bin moisture monitoring, farmers should adopt the following best practices:

Regular Testing

Conduct regular moisture checks during the storage season. A consistent schedule—such as weekly evaluations—can alert you to any potential issues before they escalate.

Proper Ventilation

Ensure your grain bins are well-ventilated to avoid condensation, one of the main culprits for increased moisture content. Utilize ventilation fans as needed to circulate air.

Data Record Keeping

Maintaining detailed records of moisture levels and storage conditions will assist in identifying trends over time. This historical data can be invaluable for future farming decisions.

Types of Grains and Moisture Content Considerations

Each type of grain has its specific moisture range for safe storage. Here’s a brief overview:

- Wheat: Ideal moisture content is around 13-14%.

- Corn: Should be stored at approximately 15% moisture for optimal conditions.

- Rice: Best stored with moisture levels no higher than 14%.

- Soybeans: Optimal storage moisture content is around 13%.

The Role of TSGC Inc. in Agriculture

At tsgcinc.com, we specialize in providing top-notch solutions for Farm Equipment Repair and Farming Equipment that complement grain bin moisture monitoring. Our experienced technicians understand the needs of modern farmers and are committed to keeping your equipment in excellent condition, ensuring you can implement effective moisture monitoring strategies with ease.

Our Services

We offer a range of services, including:

- Timely Repairs: We ensure that your equipment is running smoothly and efficiently.

- Preventative Maintenance: Regular check-ups extend the life of your farming equipment.

- Consultation: Our experts will help you choose the right equipment for your moisture monitoring needs.

Conclusion

In conclusion, grain bin moisture monitoring is not just an option but a necessity for modern farmers who value quality and profitability. By implementing advanced monitoring systems and adhering to best practices, farmers can significantly enhance their grain storage quality, prevent risks associated with spoilage, and ultimately secure better financial gains. With dedicated partners like TSGC Inc., farmers can ensure their farming equipment is always ready to support their moisture monitoring efforts. Embrace the technology and best practices today to enjoy greater yields tomorrow!