Understanding Car Body Parts Manufacturers: The Backbone of the Automotive Industry

In today’s rapidly evolving automotive industry, the role of car body parts manufacturers cannot be overstated. These entities are pivotal in the production and supply of essential parts that form the basic framework of a vehicle, ensuring its functionality, safety, and aesthetic appeal. This article delves deep into the significant contributions of car body parts manufacturers, the manufacturing processes involved, and the factors one must consider when selecting the right suppliers.

What Are Car Body Parts?

Car body parts encompass a broad range of components that contribute to the overall structure of an automobile. They include:

- Fenders: Protective panels that cover the wheels and prevent debris from being thrown into the air.

- Bumpers: Crucial components that absorb impacts and protect the rest of the vehicle in minor collisions.

- Doors: Essential for vehicle entry and exit while also contributing to the safety of passengers.

- Hoods: Cover the engine compartment, enhancing the vehicle's aerodynamics while providing easy access for maintenance.

- Trunk lids: Ensure a secure area for storage while maintaining the vehicle's seamless design.

- Roof panels: A vital part of the vehicle structure, providing rigidity and strength.

The Role of Car Body Parts Manufacturers

Car body parts manufacturers play a fundamental role in the automotive ecosystem. They are responsible for:

- Designing parts that meet OEM (Original Equipment Manufacturer) specifications.

- Utilizing advanced manufacturing techniques to produce high-quality components.

- Maintaining strict quality control measures to ensure safety and longevity of the parts.

- Responding swiftly to the evolving demands of the automotive market, including shifts towards electric vehicles.

Quality Assurance in Manufacturing

Quality assurance is integral to the manufacturing process. Reputable car body parts manufacturers employ rigorous testing methods to ensure their products meet safety standards and performance criteria. This includes:

- Material Testing: Ensuring that substances used are durable and can withstand various environmental conditions.

- Component Testing: Analyzing how individual parts function within the whole vehicle system.

- Endurance Testing: Assessing how parts perform under extended use.

- Crash Testing: Simulating impact scenarios to enhance passenger safety.

Types of Manufacturing Processes Used

Car body parts manufacturers utilize a variety of manufacturing processes to produce components efficiently and cost-effectively. Some common methods include:

- Stamping: A process that shapes metal sheets into specific parts using molds. It is widely used for components like fenders and hoods.

- Injection Molding: Used primarily for plastic components, this technique allows for complex shapes and designs.

- Welding: Essential for joining different parts together to create a sturdy structure.

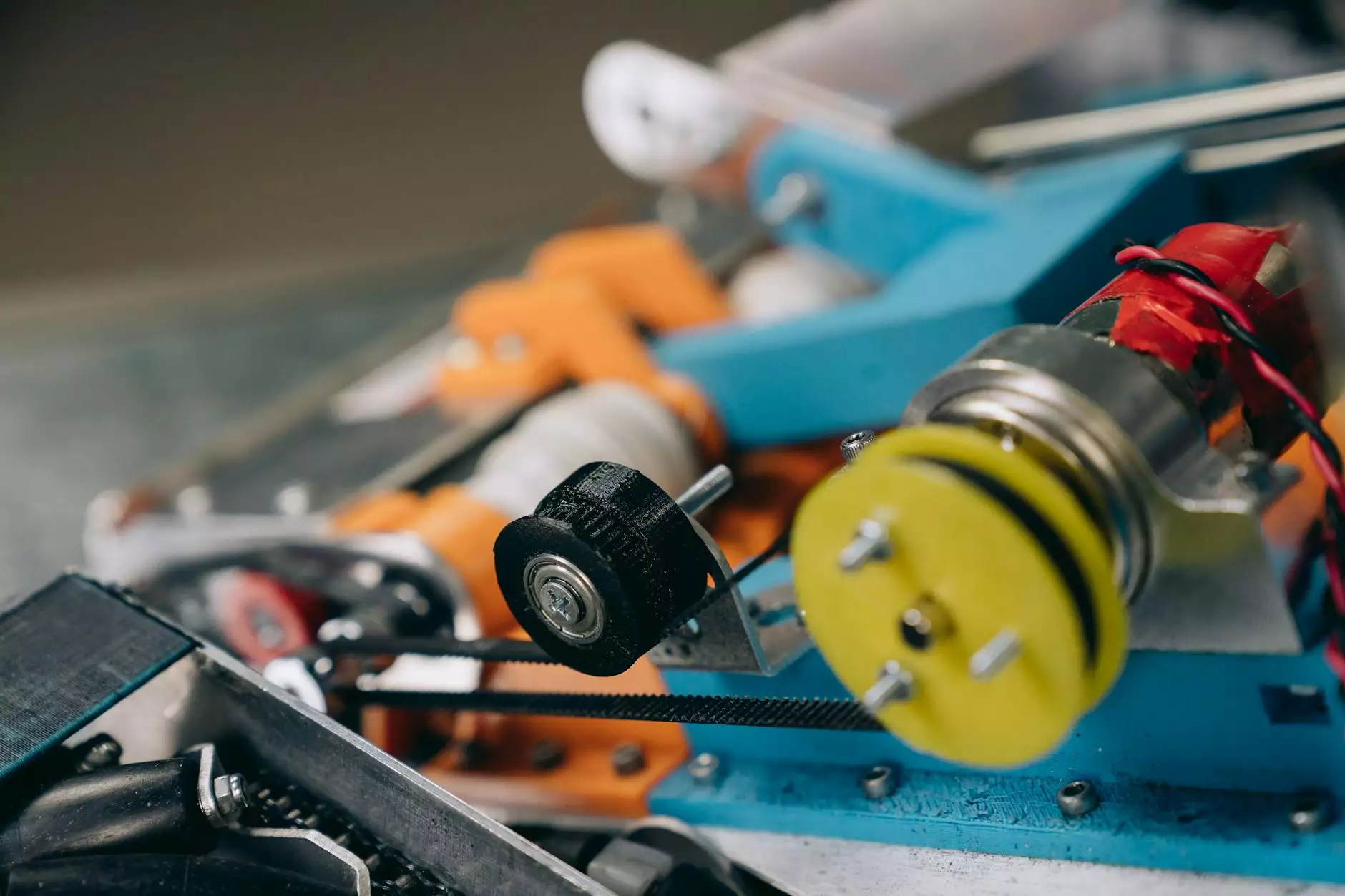

- 3D Printing: An emerging technology that allows for quick prototyping and production of custom parts.

The Importance of Supplier Relationships

Building strong relationships with car body parts manufacturers is essential for automotive businesses. The right partnership can lead to:

- Cost Savings: Long-term relationships often yield better prices and terms.

- Reliability: A trusted supplier is more likely to deliver quality products on time.

- Innovation: Collaborating with manufacturers who are at the forefront of technology can lead to enhanced product offerings.

Market Trends Affecting Car Body Parts Manufacturers

The automotive industry is undergoing significant transformations. Key trends impacting the manufacturers include:

- Electric Vehicles (EVs): As the demand for EVs rises, manufacturers are adjusting their processes to produce lighter materials that enhance efficiency.

- Automated Manufacturing: Automation is leading to faster production times and reduced labor costs.

- Sustainable Practices: There is a growing emphasis on producing eco-friendly materials and components to reduce environmental impact.

Challenges Faced by Car Body Parts Manufacturers

Despite the promising landscape, car body parts manufacturers face numerous challenges. These include:

- Supply Chain Disruptions: Global events can lead to material shortages and increased transportation costs.

- Rising Raw Material Costs: Fluctuations in the cost of metals and plastics can impact profitability.

- Regulatory Compliance: Navigating safety and environmental regulations can be complex and costly.

How to Choose the Right Car Body Parts Manufacturer

Choosing the right manufacturer is crucial for success. Here are several factors to consider:

- Reputation: Research potential manufacturers' histories and customer reviews to gauge their credibility.

- Quality Certifications: Verify that the manufacturer complies with industry standards, such as ISO certifications.

- Technology and Equipment: Ensure they are using modern technology which contributes to higher quality and efficiency.

- Customer Service: Exceptional customer support is critical in case of need for assistance or queries post-purchase.

The Future of Car Body Parts Manufacturing

The future looks bright for car body parts manufacturers as they adapt to changing market needs. With the rise of electric vehicles and advancements in technology, manufacturers have the opportunity to innovate and create components that are not only more efficient but also environmentally friendly.

Innovations on the Horizon

Several exciting innovations are emerging in the industry:

- Lightweight Materials: The shift towards materials such as carbon fiber and aluminum enhances fuel efficiency and performance.

- Smart Components: Manufacturers are exploring the integration of sensors and intelligent technology into body parts, offering more functionality and safety features.

- Recycling Technologies: Innovations in recycling processes make it easier to reuse materials, contributing to sustainability efforts.

Conclusion

The role of car body parts manufacturers in the automotive industry is indispensable. They not only provide essential components for vehicles but also contribute to the safety, performance, and evolution of automotive design. By understanding their importance, processes, and challenges, businesses can better navigate the complexities of the automotive supply chain. Investing in reliable manufacturing partners is crucial for any automotive company aiming for long-term success in a competitive market.

As we move further into the future, staying informed about market trends and technological advancements will be key to leveraging the capabilities of car body parts manufacturers. Embracing change and innovation will undoubtedly lead to a more sustainable and efficient automotive industry.